What is welding?

Welding is a technique for assembling metal elements by melting the parts to be joined.

It is one of the main assembly methods used in our everyday life for the construction of machines, vehicles and metal structures.

There are different types of welding, but the basic principle is the same: a heat source is used to fuse the parts.

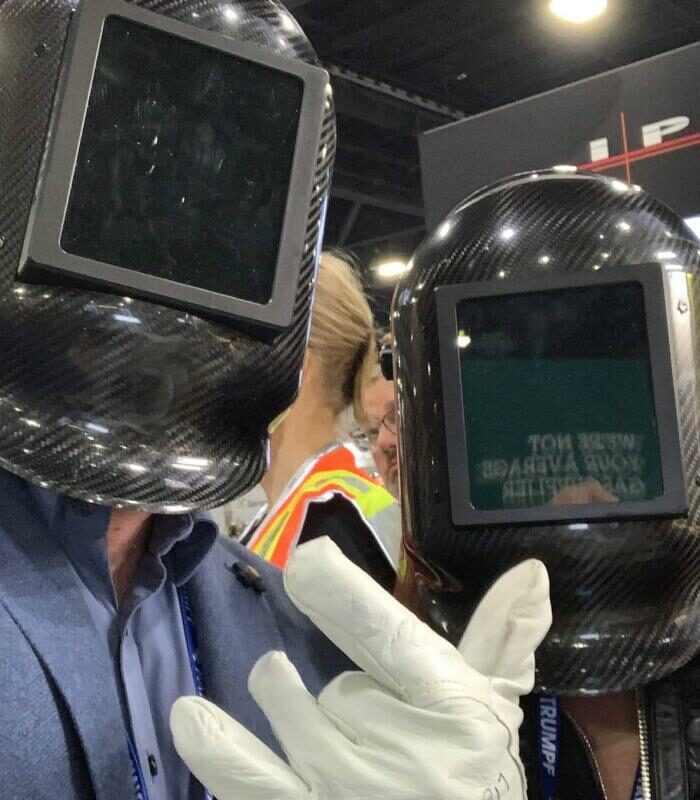

Welding involves a number of risks.

“Welding: technique of joining metal elements by melting the parts to be assembled.”

What are the main risks associated with welding?

Welding, which is the basis of all metal equipment, in particular, allows the manufacture of solid and resistant structures.

It is also its “weakest link”, as poor welding quality can lead to premature cracking and deterioration of the material, exposed to weather and temperature changes and extreme pressures.

The quality of welding is vital and to achieve it we need people, schools and companies.

Therefore, it is important to choose a good welding service provider, who has a solid experience in the field and a good command of welding quality. In France we have very good companies and we should be proud of their work and commitment.

How to protect yourself from welding risks?

To ensure quality welding, manufacturers use specially designed welding techniques and materials. They must also follow proven procedures to perform the assemblies and associated controls. In addition, welding equipment must be maintained according to the manufacturer’s specifications.

In addition, during the life of an equipment, it is recommended to regularly check the welds for cracks and deterioration.

Sometimes this recommendation takes the form of a regulatory obligation, particularly for pressure equipment, and moreover, for SEVESO sites.

These regulations are numerous and differ on various points depending on their purpose and the country that issues them.

SIRFULL, with its SaaS software Welding Cloud and Linspec Cloud, is here to simplify the task, to allow you to have a good control of the follow-up of your welds and your equipment.

SIRFULL builds the digital twin of your welding and inspection quality processes.